PHDThesis Proposed Defense Session (Mr. Hamidreza Zamani)

Title: Optimization of the type and conditions of constitutive constants determination tests for application in thermomechanical simulation of the steel hot rolling process

Presenter: Hamid Reza Zamani

Supervisor: Dr. Mohammad Reza Forouzan

Advisor: Dr. Mohammad Reza Niroomand

Reviewers: Dr. Mohammad Mashayekhi – Dr. Mahdi Salmani Tehrani

Abstract

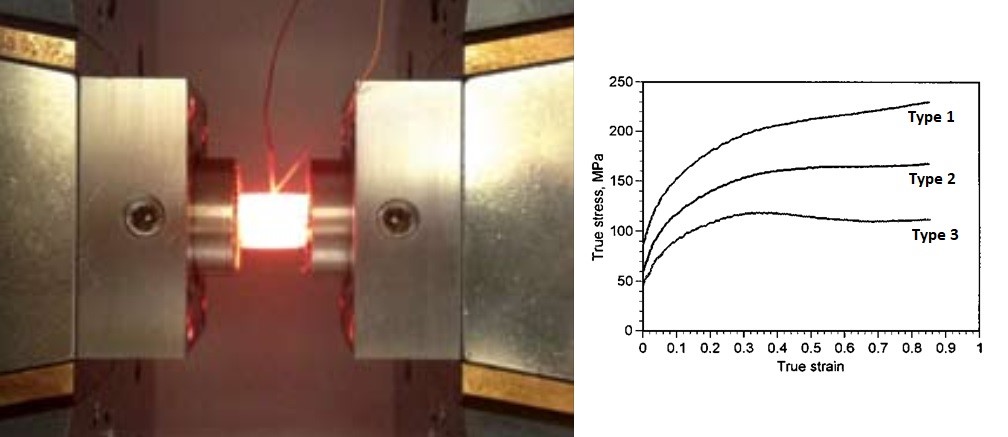

The importance and application of steel in various industries and everyday life is undeniable. Hot rolling is part of the production process for over 80 percent of steel products. Predicting and modeling the thermomechanical behavior of a grade during the hot rolling process to achieve the final product with desirable properties is a subject of interest for researchers in this field. Modeling the behavior of steel in the hot rolling process requires conducting numerous tests such as hot compression and hot torsion over a wide range of temperatures, strains, strain rates, and microstructural factors like austenite grain size, in order to understand the material's behavior from various mechanical and metallurgical aspects. Therefore, designing experiments and determining their conditions in a way that allows for an appropriate number of tests to determine suitable constants for expressing the thermomechanical behavior of the material is of great importance. On the other hand, the complex behavior of steel in hot compression and torsion tests within the hot rolling temperature range makes it difficult to establish test conditions to achieve a specific form of flow stress behavior due to phenomena such as dynamic recrystallization. This issue leads to repeated tests under new conditions until the expected response is achieved, consequently increasing the number of tests and questioning the efforts made during the experimental design aimed at reducing the number of tests. Therefore, this research will attempt to provide a systematic model for determining test conditions for characterizing each steel grade in hot rolling with two goals: minimizing the number of tests and accurately determining the thermomechanical material constants. For this purpose, it is necessary to identify the behavior of steel through a limited number of preliminary tests and then determine the optimal testing conditions based on the needs of various relationships. The overall flow stress behavior will be formulated in the form of known yield equations. The combination of thermal, mechanical, and metallurgical behaviors has led to these equations typically having a large number of material constants. To determine these constants, several initial hot compression or hot torsion tests can be conducted, and by employing mathematical methods and optimization, a selected constitutive equation for the material can be established. Then, using this constitutive equation, flow stress behaviors can be generated instead of conducting tests under various conditions. Subsequently, using optimization and machine learning-based tools, the analysis and categorization of the resulting behaviors and the specific conditions for each will be carried out, and an attempt will be made to establish a mathematical relationship between the testing conditions and the form of the resulting flow behavior. In this way, according to the objective expected from conducting the test, optimal conditions can be proposed for the main material’s characterization tests.

Keywords: Steel hot rolling, Constitutive equation, Characterization, Optimization, Design of Experiments, Flow stress, Dynamic recrystallization